Table Of Content

Non-uniform walls can cause warping of the part as the melted material cools. It is important to scrutinize surfaces such as wall surfaces, ribs, and holes in detail. As a result, plastic products are still used in the modern industrial sector the most. If all this weren't enough, plastic products are considerably less energy-intensive than metals, glass, and paper. Finding the optimum choice that addresses cost, strength and efficiency requires factoring in welding technologies, materials and the joint geometry for each application. But there are plenty of wrong materials for a particular application, and making one wrong choice can be costly and time-consuming.

unique services

Experience in the fields of product development and mechanical design engineering. Worked on numerous projects developing and innovating mechanical designs for the manufacturing of parts and assemblies in the automotive industry and electronics industry as well. Plastics engineering deals with the processing, designing, developing, and manufacturing of various plastic products. Other factors like ecological footprint reduction, innovation, and research are also key aspects of plastics engineering. If you're unsure which specialty best fits your project's needs, rely on our professional community members who can advise you in choosing the most fitting and cost-efficient method.

Guide to plastic product design and manufacturing

Polypropylene is derived from propylene gas, a byproduct of the gasoline refining process, and is commonly used to form more rigid, hardwearing items such as Tupperware, kid's toys and outdoor furniture. Due to additives like phthalate, vinyl is among the least recyclable plastics and has been linked to a number of health concerns. But latex made from the sap of the rubber tree can offer a renewable, plant-based alternative.

Fundamentals Of Plastic Part Design Part 1 – Injection Molding

This can be a guide to compare the full range of services you'll run into the market and pick your best option. Plastic product design also offers an excellent opportunity to position your product and even become a pop-culture reference. Born in 1970, Earth Day has evolved into one of the largest civic events of all time.

In the plastic product design process, it is imperative to keep the focus on the functional requirements of the product. We understand that initially, material selection may seem overwhelming since there are so many materials to choose from. You can rest easy knowing that API has partnered with resin suppliers for over 60 years and has a multitude of experience in manufacturing plastic parts with even the most difficult-to-process resins.

Our equipment mix and lower set-up times, allows us to run small jobs much more economically than many traditional in-line thermoformers. Off line set-ups can often be performed in minutes allowing multiple jobs to be completed in a single shift. Founded in 1954, UMass Lowell offers the first and largest ABET-accredited Plastics Engineering program in the U.S. More than 3,000 graduates are working in the plastics industry in leadership positions worldwide. Relevant humanities and social science courses are included with the context of engineering education to create well-rounded graduates with strong communications skills. For industries from biomedical and pharmaceutical to micro electronics and photonics, Plastic Design Inc. can supply any quantity, from the one-off prototype to full production runs.

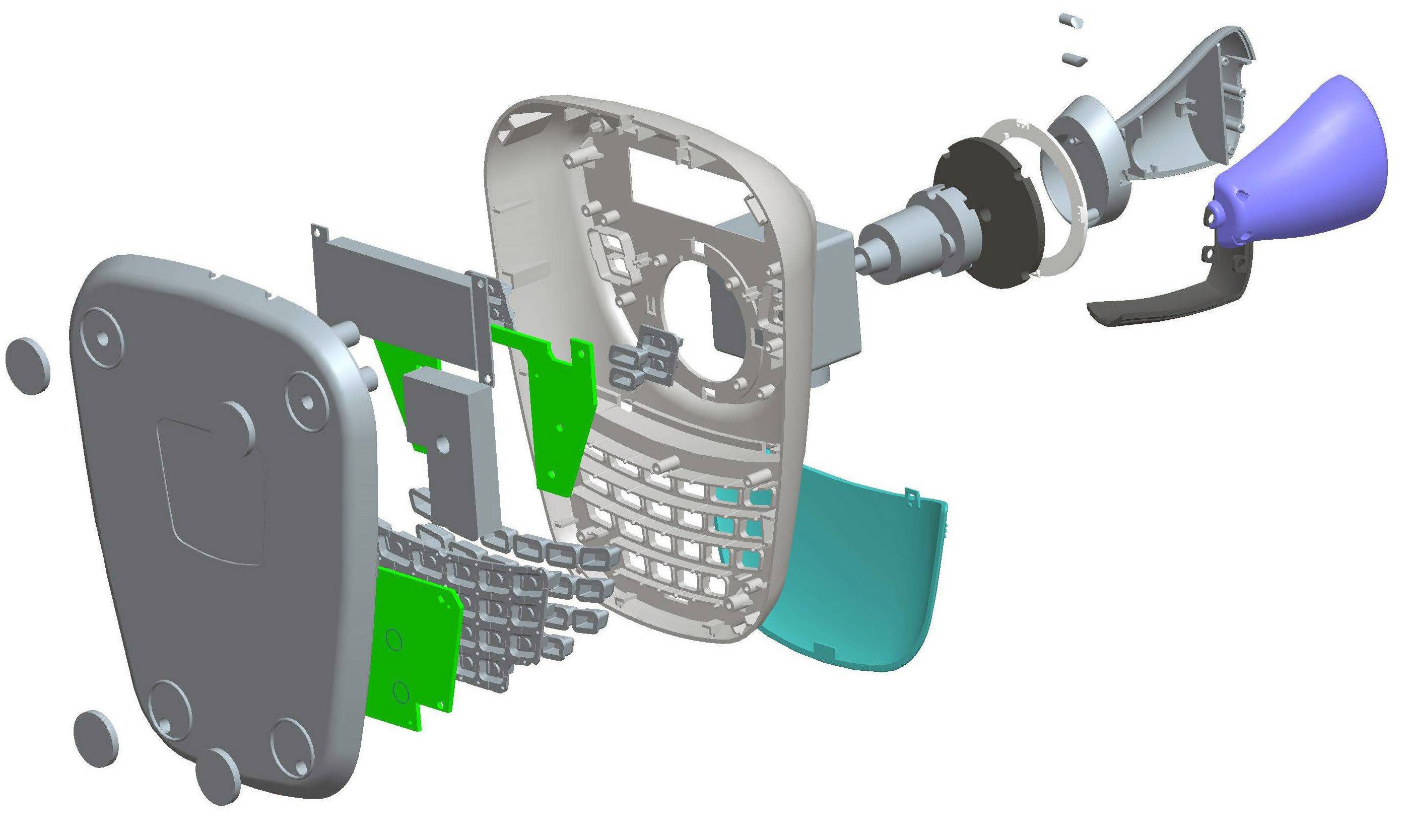

What does DFMA - Design for Manufacturing and Assembly - mean?

Researchers say accounting for plastic persistence can minimize environmental impacts - Phys.org

Researchers say accounting for plastic persistence can minimize environmental impacts.

Posted: Mon, 08 Jan 2024 08:00:00 GMT [source]

The strategy of disposal after the intended lifetime should be discussed with your team. With a deep and extensive background in precision plastic manufacturing and engineering, we’re proud to put our experience & expertise to work in our custom fabricated biomedical and pharmaceutical research products. Gussets are used in plastic parts to increase part strength in the required section. Therefore Gussets in plastic parts should be designed in a way that they should not create any venting or filling problems. Draft angle in ribs ensures easy removal of injection-molded plastic parts from the injection mold. Draft angle in injection molded parts helps in the easy removal of molded parts from the injection mold.

Complete design, tooling, and fast turnarounds are only part of the total services we offer. The UMass Lowell Plastics Engineering Department is an internationally recognized leader in plastics engineering education. The B.S. Plastics Engineering provides the expertise needed to design and manufacture environmentally sustainable products for a better world. Our plastic casework products feature a comprehensive range of unique properties that make it versatile for use in many applications in the Biomedical, Pharmaceutical, Semiconductor, and Life Science industries. SolidWorks and AutoCAD 2D or 3D are two of the programs I have been working on.

NYT hails the ubiquitous plastic chair as ‘design Holy Grail’ - Kathimerini English Edition

NYT hails the ubiquitous plastic chair as ‘design Holy Grail’.

Posted: Tue, 02 Apr 2024 07:00:00 GMT [source]

Plastic Engineering and Plastic Design

Injection-molded parts can’t be produced to the same tolerances as machined ones, so it’s important to design accordingly. A key consideration is setting tolerances that will perform in the application, without disrupting cost-effectiveness in production. Simple, rapid assembly of components can lead to significant production savings.

As an example, design for ease of assembly, using snap-fits or adhesive bonding rather than threaded fasteners. An effective product is one that has a base component for locating other components quickly and accurately. Parts should be designed so that they are within the capability of the process. DfMA allows waste or inefficiency in product manufacturing and assembly to be identified, quantified, and eliminated. The DuPont Plastic Design Guide focuses on helping users with technically effective design, properties that support material specification, and effective manufacturing techniques.

Undercuts on the part cause this blockage of path and require an action in the mold (cams, core pulls, etc.). Action in the mold can have a major impact on the cost (and overall size) of a mold. Plastic engineering expertise requires a broad knowledge of polymers, plastic molding, tool design, and requirements for the application. IDS always designs every product to comply with manufacturing practices that match your vendor’s capabilities.

The number of pieces to be manufactured is one of the most essential factors in determining the final price. A mold for a small piece can cost between 10 thousand and 20 thousand dollars, one of a much larger size can cost up to 200 thousand dollars. If all the above weren't enough, the production of most plastic products is not energy-intensive compared to metals, glass, and paper. We’re an online magazine dedicated to covering the best in international product design.

No comments:

Post a Comment